Product details

Introduction:

The Twilight Eddy Current High-efficiency Pulverizer is a scientific and technological product jointly developed by our company based on the introduction of Danish Smith's high-efficiency powder selection technology and aerospace aerodynamic analysis method and domestic famous universities and research institutes. This product integrates the plane vortex grading principle of O-SEPA separator and the finished collection method of cyclone dust removal, which makes the vortex vortex separator more cost-effective and lays a good foundation for the promotion of the vortex vortex separator. The powder sorting machine system has simple configuration, flexible process layout, high powder selection efficiency and remarkable energy saving effect. It is a new way and means for cement enterprises to improve product output under the new situation. Since the introduction of the Twilight Eddy Current Separator to the market, it has been well received by many cement companies, and users have received great economic benefits.

Working principle:

When the vortex vortex classifier is working, the variable speed motor drives the spindle to rotate through the transmission device. The material enters the center of the classifier through the feed port located at the upper part of the classifier, and then falls to the lower part of the classifier through a special blanking tube. On the sprinkling disc rotating on the main shaft, the material is evenly sprinkled around under the action of the high-speed rotating sprinkling disc. Under the action of the high-speed rotating airflow generated by the external circulating fan, the high-speed dispersing material is strongly dispersed in the material. The coarse and heavy particles (d>150μm) are smashed to the surface of the powder separation chamber by the action of inertial centrifugal force. After the collision, the kinetic energy is lost and slides along the surface of the crucible to the coarse powder cone. The rest of the material is blown up by the rotating airflow and continues to rise. A portion of the coarse particles are sorted and dropped into the coarse powder cone.

The material (d<150μm) sorted by the spreading disc and the large wind blade continues to rise into the precise grading area: the plane vortex grading area, and the dusty airflow is under the strong and stable plane vortex formed by the rotating cage rotor. The coarse powder that does not meet the requirements of the finished product is further accurately selected. The inertial centrifugal force generated by the coarse particles is greater than the centripetal suction force formed by the rotor, and the coarse particles are thrown to the surrounding vertical guide vanes, and the kinetic energy is lost after the impact. In the middle coarse powder cone, it is discharged through the medium coarse powder lock valve. The fine powder (d < 60 μm) that meets the requirements enters the interior through the cage, and the optional powder gas flows into a cyclone disposed around the milling chamber and is collected into a finished fine powder.

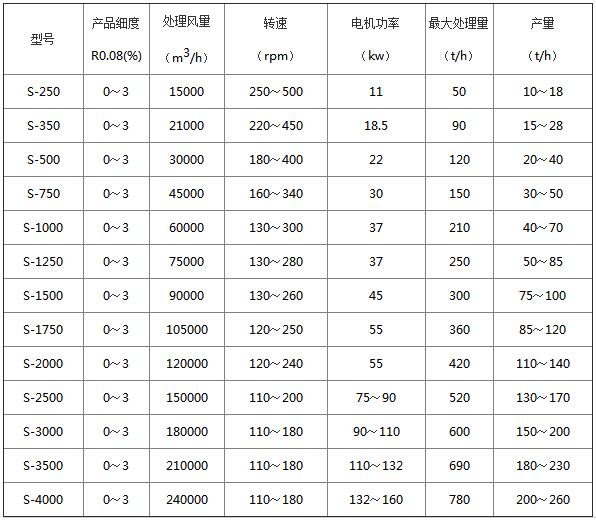

Technical Data:

Previous page:Bucket elevator

Next page:Ball mill

TEL:0086-13523465141

0086-371-67666660

FAX:0086-371—68125111

Email:shuguang_mill@163.com

Address:No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China