Product details

Product Application:

Building materials products include construction materials and products, non-metallic minerals and products, and inorganic non-metallic new materials. They are widely used in fields such as construction, military industry, environmental protection, high-tech industries, and people's lives.

The quality of building materials continues to increase, energy and raw material consumption are declining year by year, new types of new building materials continue to emerge, and building materials are constantly upgraded. As a result, the requirements for the processing technology of building materials have been continuously improved. For example, the control requirements for impurities and moisture content of raw materials have been continuously improved. Only in this way can products with guaranteed quality be produced.

Mine dryer is a new product that appears according to the needs of product quality processing and production. The mine dryer takes into account such links as environmental protection and energy saving. Therefore, the research and development expenditure of R&D expenditures is based on reducing pollution, reducing losses, saving floor space, and providing productivity, and a new generation of products developed through multi-disciplinary research and planning by professional and technical experts. . The size of the equipment can be properly adjusted according to the actual application of the building materials industry to meet the processing requirements for different materials.

Heat Source:

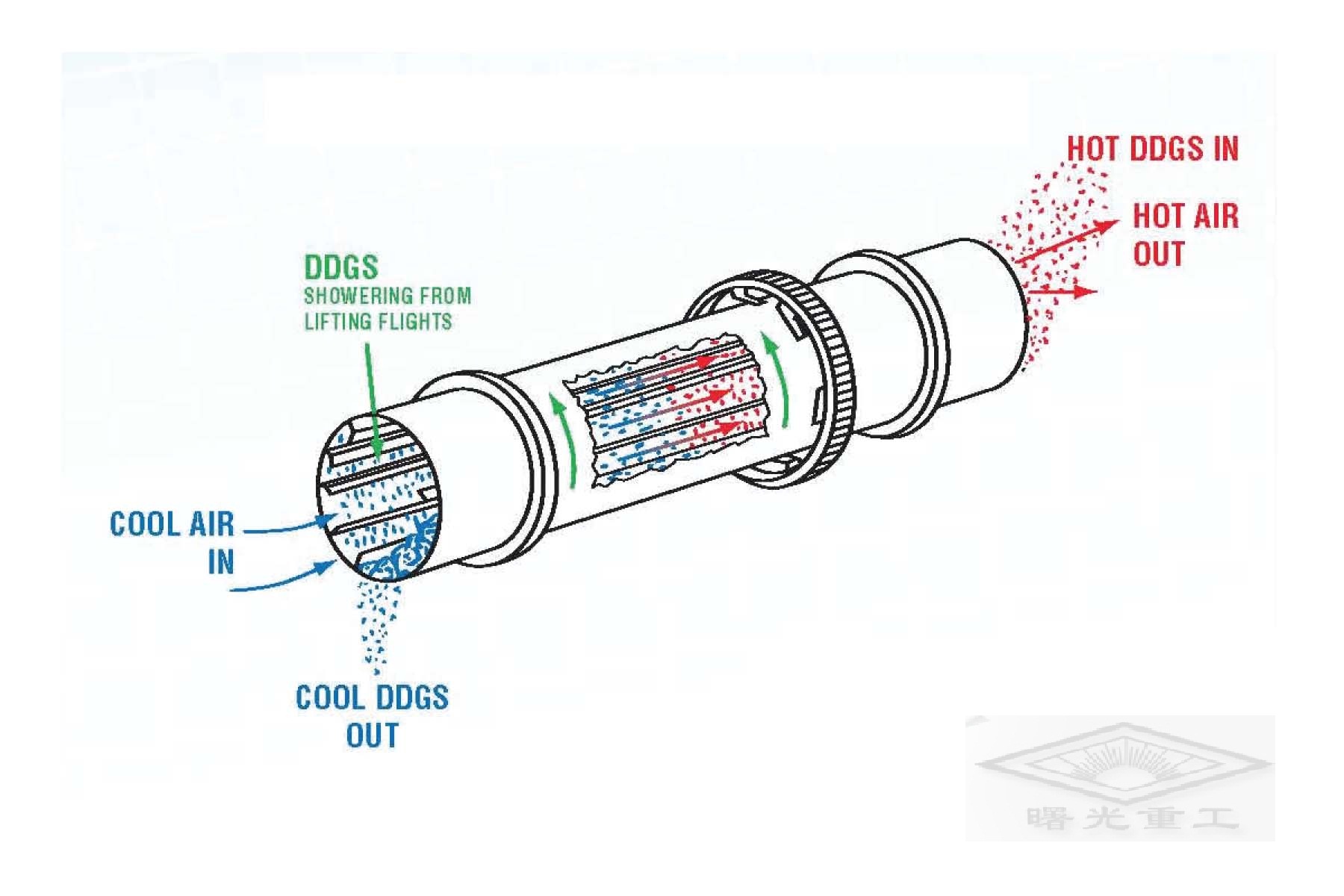

The heat source of the dryer is coal, electricity, gas, etc.Material hot atmosphere flow during drying and radiant, hot air drying cylinder is the heat flow from the tail, to move forward with a good contact with the material, through the heat conduction, convection and radiation heat transfer make full use of;Pass heat directly to the material, make the material moisture to evaporate in the cylinder body are constantly being, into the mouth of the wind device take out a large number of moisture, wet, prevent secondary pollution caused by the dust outside;Through internal spiral stirring, scavenging, copying plate, press the material movement, complete the drying process;Reverse flow dehumidification to avoid reducing repeat drying procedures.

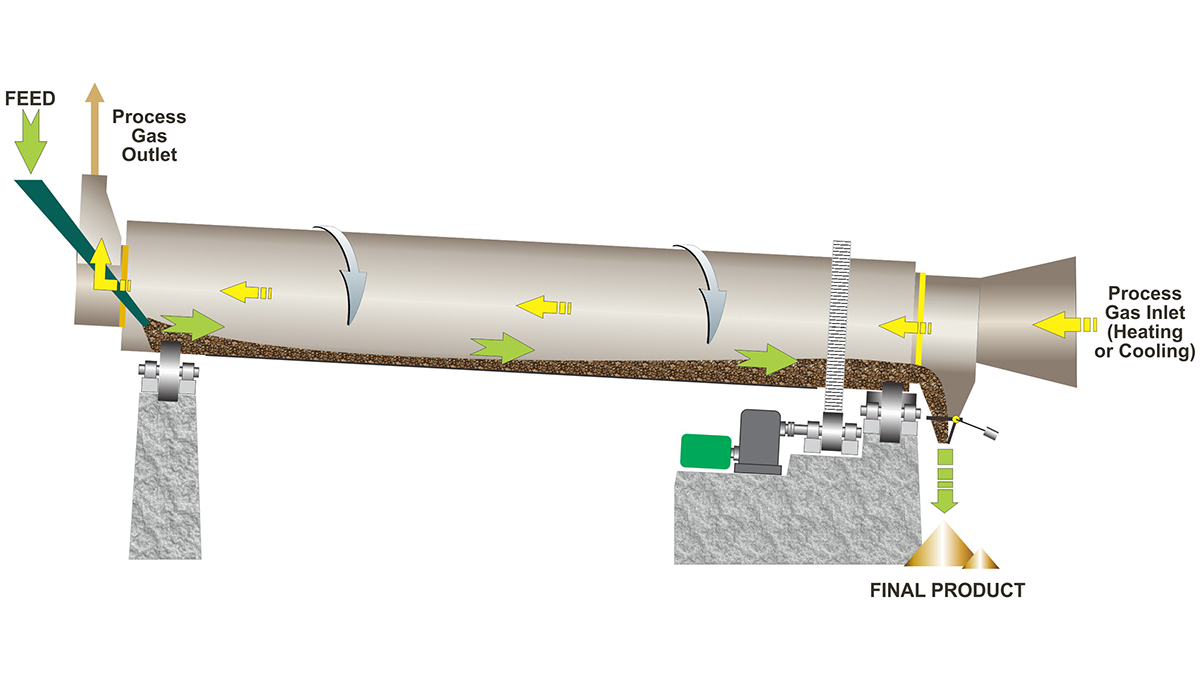

Work Principle:

The wet material is sent to the hopper by the belt conveyor or the bucket elevator, and then through the feed pipe to the feeding end through the feeder of the hopper. The slope of the feed pipe is greater than the natural inclination of the material so that the material can flow smoothly into the dryer. The dryer cylinder is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end, and the heat carrier enters from the low end, and is in countercurrent contact with the material. There is also a heat carrier and the material flow into the barrel together. As the cylinder's rotating material is moved by gravity to the bottom end. During the forward movement of the wet material in the cylinder body, the heating of the heating medium is obtained directly or indirectly, so that the wet material can be dried, and then sent out at the discharge end via a belt conveyor or screw conveyor. A copy board is installed on the inner wall of the barrel, and its function is to copy the materials and scatter them, so that the contact surface of the materials and the air flow is increased, so as to increase the drying rate and promote the advancement of the materials. Heat carrier is generally divided into hot air, flue gas and so on. After the heat carrier passes through the dryer, a cyclone dust collector is generally required to trap the material contained in the gas. If it is necessary to further reduce the dust content of the tail gas, it should also be discharged after bag filter or wet filter.

Main Features:

1. The drying strength is high, and since the materials are highly dispersed in the gas stream, the entire surface of the particles is actively dry and effective.

2. Short drying time.

3. The air dryer has a simple structure, a small footprint, and is easy to build and maintain.

4. Large amount of processing, high thermal efficiency. When drying unbound water, the thermal efficiency can reach 60%.

5. The dryer achieves "zero horizontal thrust", which greatly reduces the wear of the brace wheel and ensures smooth and reliable operation of the barrel.

6. Dryer adopts "aligning roller device", so that the support of the roller and the roller will always be in linear contact, thus greatly reducing wear and power loss.

Technical:

|

Model (mm) |

Gradient (%) |

Rotation Speed (r/min) |

Feed-in Gas Temperature (°C) |

Power (kw) |

Output (t/h) |

Weight (t) |

| 600x6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| 800x8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| 800x10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| 1000x10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| 1200x10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| 1200x12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| 1500x12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| 1800x12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| 2200x12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| 2200x18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| 2200x20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| 2400x20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| 3000x20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| 3000x25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Previous page:Rotary Drum Dryer/Plate Dryer

Next page:Leather shredder

TEL:0086-13523465141

0086-371-67666660

FAX:0086-371—68125111

Email:shuguang_mill@163.com

Address:No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China