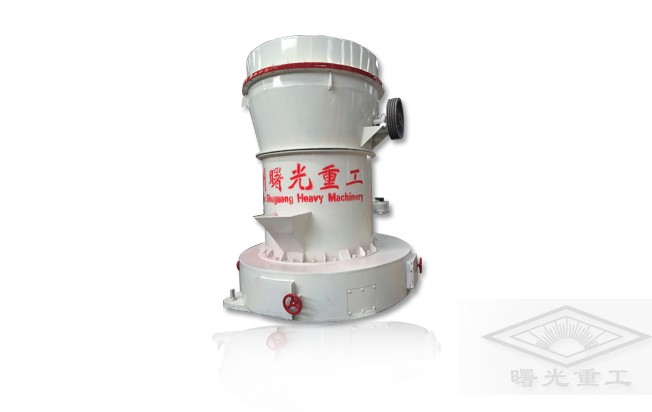

Product details

Application:

This machine is widely used in quartz, recrystallization, calcite, potassium feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass. , manganese ore, titanium ore, copper ore, chrome ore, refractory materials, thermal insulation materials, coal char, coal powder, carbon black, clay, bone powder, titanium dioxide, iron oxide, etc. Mohs hardness below 9.3, humidity below 6% High-quality milling of more than 300 materials in non-flammable and explosive minerals, construction, chemical, fertilizer and other industries. The finished product size is in the range of 60-325 mesh (0.125 mm - 0.044 mm). The highest fineness of the material can reach 1000 mesh (0.013 mm).

Working process:

The whole structure of Raymond Mill is composed of main machine, analysis machine, pipeline device and blower. It can be equipped with crusher, hoist, electromagnetic vibrating feeder and electric control motor according to user needs. After the material is pulverized to the required particle size, the material is sent to the storage hopper by the hoist, and then the material is uniformly and continuously fed into the main machine grinding chamber through the vibrating feeder, and the grinding roller swings outward due to the centrifugal force during rotation. In the grinding ring, the blade shovel the material between the grinding roller and the grinding ring, and the grinding roller achieves the purpose of pulverizing. The fine powder after grinding of the material is brought into the analysis machine for sorting with the circulating wind of the blower, and the finely coarse material falls back to the regrind, and the qualified fine powder enters the finished cyclone powder collector with the airflow, and is discharged through the powder discharging pipe. That is the finished product. In the grinding chamber, there is a certain amount of moisture in the material to be ground, heat is generated during grinding, water vapor evaporates, and the pipelines of the whole machine are not tightly connected, the outside air is sucked in, the circulating air pressure is increased, and the mill is operated under negative pressure. The increased air flow is discharged into the dust remover through the residual air duct, and is purified and discharged into the atmosphere.

Features:

1. Raymond mill has a small footprint and a complete set of products. It can be independently produced from the block material to the finished product packaging.

2. The sieve size of the finished product after Raymond mill grinding can reach more than 99%, which is not suitable for other mills.

3. The electromagnetic vibrating feeder is uniform in feeding, easy to adjust, small in size, light in weight, fuel-efficient and power-saving, and easy to maintain.

4. The electric adopts centralized control and advanced selection, and can realize unmanned operation in the host computer room.

5. The main drive unit adopts a closed reducer, which has stable transmission, reliable operation and no leakage of oil.

6. The main blade holder is always in contact with the material during operation, so the blade holder is composed of upper and lower parts. After the lower seat is worn, the disassembly connection bolt can be changed.

Technical data:

| Model | 6R4525 | 5R4121 | 5R4119 | 4R3218 4R3220 | 4R3216 | 4R3016 | 3R3015 4R3015 | 3R2715 | 3R2615 | 3R2115 | 3R1510 |

| Feeding size(MM) | ≤30 | ≤30 | ≤25 | ≤25 | ≤25 | ≤25 | ≤20 | ≤20 | ≤20 | ≤15 | ≤15 |

| Final size (MM) | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 | 0.125-0.044 |

|

Output (T/H) |

13-40 | 8-15 | 5-10 | 2.5-9 | 2-8 | 1-5 | 1-4 | 0.9-3.5 | 0.7-3 | 0.5-1.6 | 0.2-0.8 |

| Speed (R/M) | 82 | 105 | 105 | 130 | 130 | 160 | 160 | 160 | 160 | 180 | 280 |

| Diameter of ring(MM) | 1620 | 1270 | 1270 | 970 | 970 | 880 | 830(800) | 830 | 780 | 650 | 410 |

| Diameter of roller (MM) | 450 | 410 | 410 | 320 | 320 | 300 | 270 | 270 | 260 | 210 | 140 |

| Height of roler(MM) | 250 | 210 | 190 | 180/200 | 160 | 160 | 150 | 150 | 150 | 150 | 100 |

| Main motor (KW) | y315m-4-132 |

y280s- 4-75 |

y280s- 4-75 |

y225s- 4-37 |

y225s- 4-37 |

y225m- 8-30 |

y225m-8-22/30 |

y225m- 8-22 |

y225s- 8-18.5 |

y200L- 8-15 |

y160m- 6-7.5 |

| Fan motor (KW) | y315m-4-132 |

y250m- 4-75 |

y250m-4-75 |

y200L- 4-37 |

y200L- 4-37 |

y200L- 4-37 |

y160L-4-18.5 |

y160L- 4-18.5 |

y160L- 4-15 |

y160m-4-11 | y132s-4-5.5 |

| Anlysis motor (KW) | y160m-4-11 |

yc200- 4-7.5 |

yc200- 4-7.5 |

yc120- 4-5.5 |

yc120- 4-5.5 |

y112m- 6-5.5 |

y112m-6-2.2 |

y112m- 6-2.2 |

y112m- 6-2.2 |

y112m- 6-2.2 |

y90L- 6-1.1 |

Previous page:3R Raymond mill

Next page:4R Raymond mill

TEL:0086-13523465141

0086-371-67666660

FAX:0086-371—68125111

Email:shuguang_mill@163.com

Address:No.104,Gongye west road,Shangjie district,Zhengzhou City,Henan China